Technical Parameter

| Nazivni napon | Nazivna struja | Znak otporan na eksploziju | Protection level | Corrosion protection level |

|---|---|---|---|---|

| 380V | ≤250A | Ex db eb mb px IIC T4 Gb | IP65 (Air pipeline chamber IP54) | WF1 |

| User air supply pressure | Setting pressure of pressure regulating filter | Normal working pressure range | Lower limit of alarm pressure | Upper limit of alarm pressure | Lower limit of power cutoff pressure | Upper limit of power cutoff pressure |

|---|---|---|---|---|---|---|

| 0.3~0.8MPa | 0.05MPa | 100~500Pa | 60~100Pa | 500~1000Pa | <60Pa | >1000Pa |

| Type of protective gas | Gas temperature | Ventilation duration | Corrosion protection level |

|---|---|---|---|

| Clean air or inert gas | ≤40℃ | 10min | WF1 |

Karakteristike proizvoda

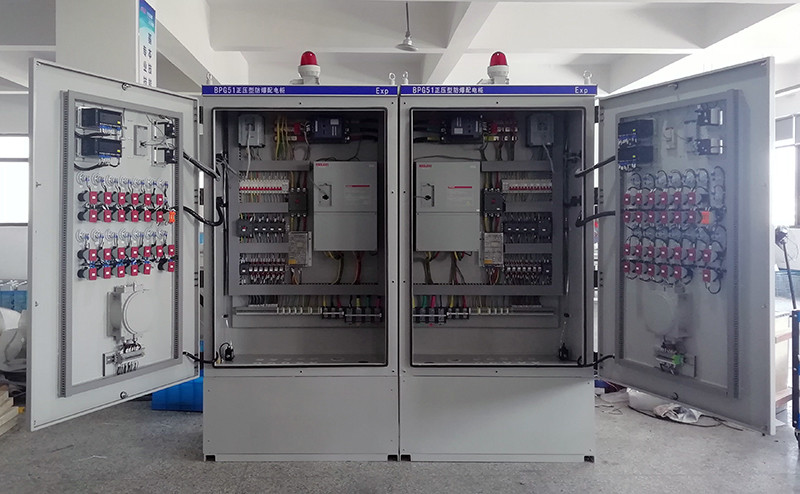

1. The shell is made of high-quality carbon steel or stainless steel welded and formed, with high-pressure electrostatic spraying treatment on the surface, which is corrosion-resistant, anti-static, firm and reliable;

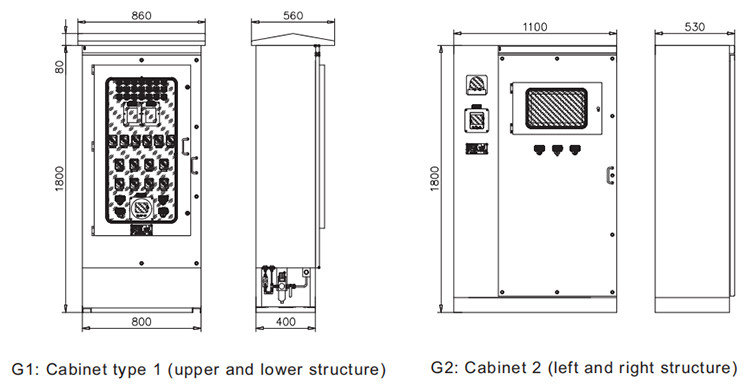

2. Modular structural design, positive pressure chamber and control chamber can be combined in various ways such as up and down, left and right, front and rear, or can be installed separately;

3. Equipped with a gas pressure regulating and filtering device, users only need to introduce on-site industrial gas sources and do not need to install other gas source components;

4. Equipped with spark and particle baffles, the positive pressure chamber can discharge gas locally, ensuring safety and reliability;

5. The control system adopts a PLC programmable logic controller, which is stable, reliable, and has fast response speed;

6. Humanized human-machine interface, LCD text display, integrating multiple functions, reducing control system panel buttons and indicator lights;

7. Equipped with communication interface, it can achieve remote centralized monitoring and control;

8. Real time monitoring of important parameters such as positive pressure chamber pressure and flow rate;

9. The sensor signal type and signal value range can be set;

10. The delay time before formal air change can be set to ensure that combustible gases are completely discharged before the positive pressure chamber is powered on;

11. According to the on-site gas source pressure situation, the working pressure range, alarm pressure range, and positive pressure chamber power cut-off pressure range can be set by oneself;

12. Set the size of the positive pressure chamber according to the actual situation to improve the universality of the control program;

13. The program automatically calculates the duration of ventilation based on relevant parameters;

14. Modular program design, which can achieve different control functions by simply loading different programs;

15. Equipped with a system fault analysis program and flashing text on the human-machine interface to prompt users for easy maintenance;

16. Various detection instruments, analysis instruments, display instruments, low-voltage electrical appliances, frequency converters, soft starters, and various electrical control systems can be installed in the positive pressure chamber, making it flexible and versatile.

Primjenjiv opseg

1. Suitable for eksplozivno gas environments in Zone 1 i Zona 2 locations;

2. Suitable for places in Zone 21 i Zona 22 with combustible dust environments;

3. Suitable for Class IIA, IIB, and IIC explosive gas environments;

4. Suitable for temperaturu groups T1 to T6;

5. It is applicable to dangerous environments such as oil exploitation, preradu nafte, hemijska industrija, gas stations, offshore oil platform, tankeri za naftu, obrada metala, lijek, itd;

6. Suitable for explosion-proof treatment of products with large volume, high working temperature rise of internal components, or complex electrical circuits;

7. There are two types of treatment: dilution airflow and leakage compensation.

Shenhai otporan na eksploziju

Shenhai otporan na eksploziju