Explosion-proof enclosures are the most widely used distribution devices, offering comprehensive protection. The most common types are flameproof and pressurized explosion-proof enclosures, catering to a variety of requirements. Many users wonder about the differences between these two types. Here, we provide an insight into the distinctions between flameproof and pressurized explosion-proof enclosures.

Explosion Protection Principle:

Flameproof Enclosures:

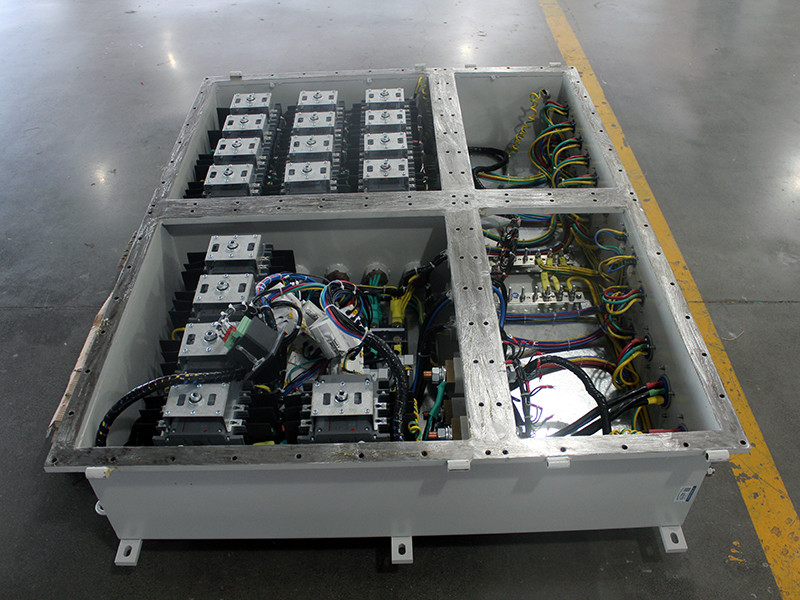

As the name implies, these enclosures isolate explosions. They house electrical components that may produce sparks, arcs, or dangerous temperatures, separating the internal space from the external environment. The enclosure can withstand the impact of internal explosions, sustaining the explosion pressure without damage. The gaps in the enclosure structure also cool down flames, reducing the speed of flame propagation or stopping the acceleration chain, thus preventing flames or arcs from reaching the external explosive environment and achieving the flameproof purpose.

Pressurized Enclosures:

These enclosures are filled with fresh air or inert gas (compressed air) at a certain pressure to prevent external combustible gases from entering. This keeps the explosive gases from coming into contact with internal ignition sources, thus preventing explosions.

Usage:

Flameproof protection is achieved through the physical structure of the enclosure and requires only standard commissioning for use.

Pressurized types require a gas supply (such as instrument air, air compressors, gas cylinders), connecting the air supply pipe to the inlet interface of the enclosure. Once pressurized and adjusted, they can function normally.

Functionality:

Flameproof distribution boxes offer basic functions like distribution, control, power supply, remote operation, overload protection, short-circuit protection, leakage protection, and photocontrol. However, they have limitations, such as inadequate heat dissipation, overheating protection with high-power components, and unresolved issues with explosion-proof touch screens. Adding a touch screen protective door can lead to failure.

Pressurized enclosures not only possess some functions of flameproof types but also feature interlocking alarms, automatic re-pressurization, pressure relief, remote monitoring, and high electrical automation. They can meet any industry’s explosion-proof requirements with robust heat dissipation capabilities. Large power inverter heat issues can be resolved by adding an explosion-proof air conditioning unit. Since pressurized explosion-proofing does not require flameproof surfaces, touch screens can be directly installed on the enclosure with windows.

Pricing:

The price difference between flameproof and pressurized types primarily stems from their size, with pressurized materials being generally smaller.

With this comprehensive comparison of flameproof and pressurized explosion-proof enclosures, users should now understand the differences between the two and can make informed choices when purchasing based on specific needs.

Shenhai Explosion-Proof

Shenhai Explosion-Proof