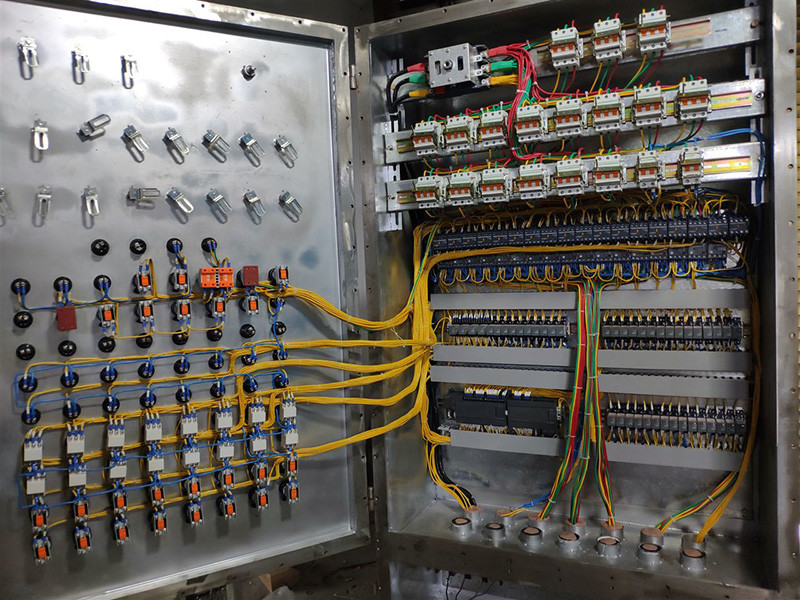

Explosion-proof products have stringent requirements for wiring, cable usage, and grounding methods, differing from regular electrical products.

Allowable Current Capacity

For zones 1 and 2, the permissible current carrying capacity of the conductor in the explosion-proof box should be no less than 1.25 times the rated current of the fuse element and the rated current of the circuit breaker’s long-delay overcurrent release. For branch circuits of low-voltage cage asynchronous motors, the allowable current capacity should be no less than 1.25 times the motor’s rated current.

Wire Material Selection

Within the explosion-risk zone level 2, power supply lines should use aluminum core wires or cables with a cross-section of 4mm² or larger, while lighting circuits can use a cross-section of 2.5mm². In explosive environments of risk level 1, distribution circuits should use copper core wires or cables. In places with significant vibration, stranded copper core flexible wires or cables should be chosen. The use of aluminum core cables is not permitted in coal mine shafts.

Electrical Circuit Connection

When opting for aluminum core cables or wires, reliable intermediate joints for zone 1 electrical circuits are necessary within the explosion-proof box. For zone 2, these intermediate joints must be within or near a junction box in the hazardous environment. Explosion-proof junction boxes are recommended for zone 1, while increased safety junction boxes are suitable for zone 2.

Isolation and Sealing

When laying electrical lines in trenches or conduits, and crossing through walls or floors separating areas with different explosion risk levels, non-combustible materials must be used for sealing.

Select the installation location, laying method, conductor material, and connection method for explosion-proof electrical equipment circuits based on the environmental risk level. The placement of explosion-proof electrical equipment should consider laying electrical lines in areas with lower explosion risks or further from the leak sources.

The above is a brief overview of the protection of electrical wires in explosion-proof boxes. Specific considerations should be based on actual circumstances. Explosion-proof boxes have cable glands and compression screws for the outgoing cables. Ensuring safety involves passing the cable through the gland and compression screw, tightening it so the seal closes the gap around the cable exit, preventing any sparks from escaping.

Shenhai Explosion-Proof

Shenhai Explosion-Proof