When selecting an explosion-proof distribution box, several factors must be considered to ensure it meets specific requirements. This includes the application environment, such as underground wells, coal mines, oil plants, flour mills, gas plants, etc. The choice of a distribution box depends on the different hazardous factors in these environments, with higher protection levels often resulting in higher prices.

1. Application Suitability:

Choose a distribution box that suits your specific environment and needs. The hazardous factors vary in different settings, demanding distinct types of boxes. The higher the protection level required, the higher the cost tends to be.

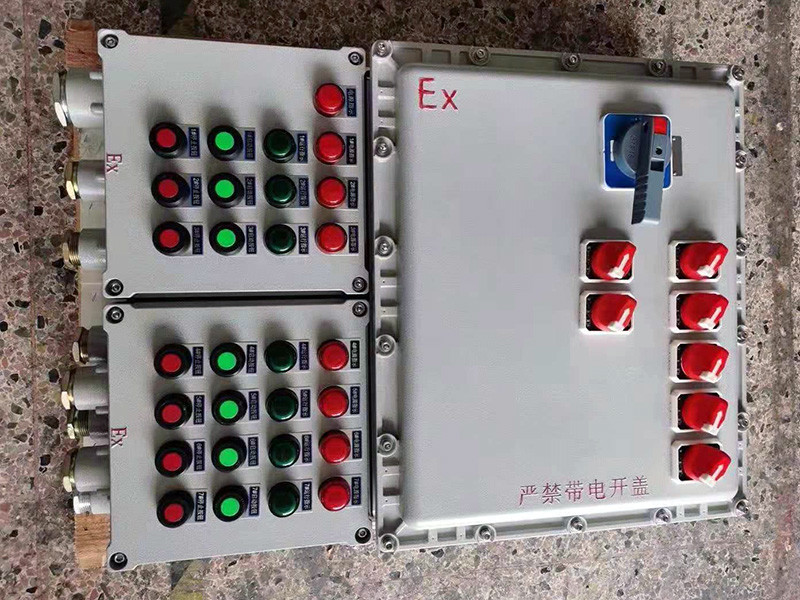

2. Size and Material:

The size and material of the box significantly influence its price. Larger sizes mean more materials and a more complex internal structure, leading to higher costs. The price difference between metal and plastic materials also plays a role.

3. Explosion-Proof Rating:

Different explosion-proof ratings cater to various explosive factors like gases, liquids, solids, and powders. The production materials and techniques vary accordingly. Higher explosion-proof ratings usually mean greater manufacturing complexity, inevitably impacting the cost.

4. Brand Influence:

Well-known brands with a broad customer base often leave little room for price negotiation. Conversely, smaller brands aiming to establish a market presence may offer discounts to secure a sale, thus affecting the price.

Currently, there is no standard price or specification for explosion-proof distribution boxes; hence, they are not typically sold at fixed prices. Pricing is generally based on specific designs and blueprints. As custom-made, non-standard products, the cost of explosion-proof lighting distribution boxes depends on the specific parameters requested.

Shenhai Explosion-Proof

Shenhai Explosion-Proof