『Click here to download the product PDF: Explosion Proof Sealing Box BGM』

Technical Parameter

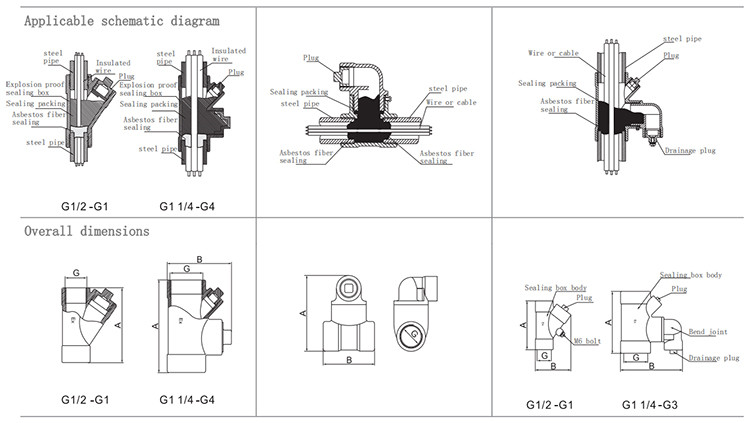

VERTICAL TYPE

| Thread specifications | BGM-Z | Cable outer diameter(φmm) | |

| A | B | ||

| G1/2 | 77 | / | 8~10 |

| G3/4 | 87 | / | 10~14 |

| G1 | 110 | / | 12~17 |

| G1 1/4 | 130 | 87 | 15~23 |

| G1 1/2 | 130 | 92 | 17~26 |

| G2 | 140 | 107 | 25~35 |

| G2 1/2 | 175 | 129 | 29~38 |

| G3 | 190 | 139 | 33~51 |

| G4 | 225 | 162 | 41~72 |

HORIZONTAL TYPE

| Thread specifications | BGM-H | Cable outer diameter(φmm) | |

| A | B | ||

| G1/2 | 94 | 74 | 8~10 |

| G3/4 | 100 | 74 | 10~14 |

| G1 | 106 | 74 | 12~17 |

| G1 1/4 | 114 | 98 | 15~23 |

| G1 1/2 | 134 | 98 | 17~26 |

| G2 | 142 | 120 | 25~35 |

| G2 1/2 | 185 | 185 | 29~38 |

| G3 | 193 | 193 | 33~51 |

DRAINAGE TYPE

| Thread specifications | BGM-P | Cable outer diameter(φmm) | |

| A | B | ||

| G1/2 | 88 | 61 | 8~10 |

| G3/4 | 100 | 74 | 10~14 |

| G1 | 111 | 84 | 12~17 |

| G1 1/4 | 130 | 116 | 15~23 |

| G1 1/2 | 130 | 121 | 17~26 |

| G2 | 140 | 143 | 25~35 |

| G2 1/2 | 175 | 181 | 29~38 |

| G3 | 190 | 191 | 33~51 |

Product Features

1. Cast aluminum alloy shell with high-pressure electrostatic spraying on the surface;

2. The longitudinal type (Z) has a cast steel shell, please indicate it when ordering;

3. Adopting pipe thread connection, metric thread and NPT thread can be customized;

4. Good sealing and explosion-proof performance;

5. Multiple product specifications to meet on-site installation needs;

6. Explosion proof sign Ex db II CGb/Ex tb III C T80 ℃ Db.

Applicable Scope

1. Suitable for explosive gas environments in Zone 1 and Zone 2 locations;

2. Suitable for places in Zone 21 and Zone 22 with combustible dust environments;

3. Suitable for Class IIA, IIB, and IIC explosive gas environments;

4. Suitable for the T1-T6 temperature group;

5. Widely used for clamping and sealing cables in hazardous environments such as oil extraction, refining, chemical engineering, and gas stations.

Shenhai Explosion-Proof

Shenhai Explosion-Proof